Photoresist has one of the highest technical barriers in semiconductor materials.

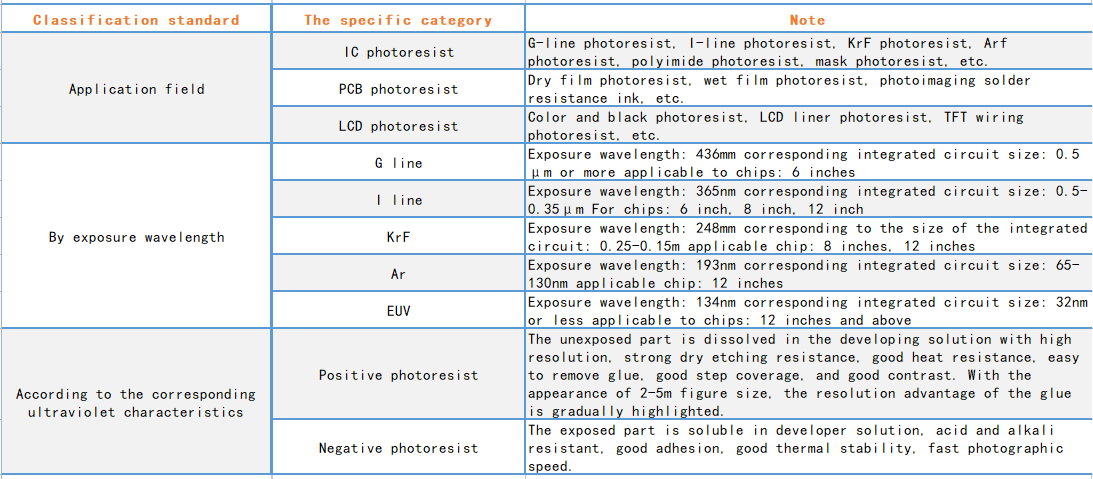

Photoresist is a typical technology-intensive industry with a variety of products and strong specificity. Different uses of photoresist exposure light source, reaction mechanism, manufacturing process, film formation characteristics, processing graphics line accuracy and other performance requirements are different, resulting in different requirements for the material's solubility, etching resistance, photographic properties, heat resistance and other requirements. Therefore, the raw materials used in each type of photoresist are special in chemical structure and performance, requiring the use of different quality grades of photoresist special chemicals.

Photoresist generally consists of four components: resin-based polymers, photoactive substances, solvents and additives. Resin is the largest component in photoresist, constitutes the basic skeleton of photoresist, and mainly determines the basic properties of photoresist after exposure, including hardness, flexibility, adhesion, corrosion resistance, thermal stability, etc. Photoactive substance is the key component of photoresist and plays a decisive role in its sensitivity and resolution.

Resolution, contrast and sensitivity are the key technical parameters of photoresist. With the development of integrated circuit, the characteristic size of chip manufacturing is becoming smaller and smaller, and the requirement of photoresist is becoming higher and higher. The key technical parameters of photoresist include resolution, contrast and sensitivity. In order to meet the needs of the development of integrated circuits, photoresist is developing towards high resolution, high contrast and high sensitivity.

Take you to understand the types and characteristics of photoresist, there are the following:

Photoresist can be divided into positive photoresist and negative photoresist according to the polarity of its formation pattern.

Orthogum refers to the long chain molecules of polymers that are truncated by light into short chain molecules; Negative adhesive refers to the short chain molecules of a polymer that cross the long chain molecules due to light. The short chain molecular polymer can be dissolved by the developer, so that the exposure of the positive adhesive is removed, while the exposure of the negative adhesive is retained.

(1) Uv resist:

Various processes: special spray glue, chemical magnifying glue, lift-off glue, graphic reversal glue, high resolution glue, LIGA glue, etc.

Photoresist for various wavelengths: Deep UV, I-line, G-line, longwave exposure.

Various thickness: photoresist thickness can be from tens of nanometers to hundreds of microns.

(2) Electron beam photoresist (ELECTRON beam resist) :

Electron beam glue: PMMA glue, PMMA/MA polymer, LIGA glue, etc.Electron beam negative adhesive: high resolution electron beam negative adhesive, chemical magnifying adhesive (high sensitivity electron beam adhesive), etc.

(3) photoresist for special process: electron beam exposure conductive adhesive, acid and alkali resistant protective adhesive, holographic photoresist adhesive, polyimide adhesive (high temperature resistant protective adhesive) and other special process adhesive.

(4) Supporting reagents: developer, glue solution, diluent, additive (adhesion agent), fixing solution, etc.