As a core material that has a significant impact on the image quality and performance of LCDs and OLEDs, photosensitive materials form precise images and are liquid chemical substances with photosensitive properties, and are products that combine cutting-edge technologies such as semiconductor process technology, photo-etching technology, materials engineering, and precision chemistry.

Here we introduce a material for OLEDs, photoresist. OLED material manufacturer shares with you its characteristics, process and classification.

Photoresist Processing

Photolithography is the process of defining areas or patterns on a wafer where material is to be deposited or removed or where dopants are to be introduced. An important aspect of photolithography is photoresist processing, a process that covers areas that either need to be subsequently removed or retained with a photosensitive film called photoresist. The material removal process that follows the photolithography process is called etching.

Basic functions.

1) Precise pattern formation.

2) Protection of the substrate from chemical attack during the etching process.

Production steps.

1) dehydration and priming; 2) resist coating; 3) soft baking; 4) exposure; 5) development; and 6) post-development inspection.

Photoresist Classification

There are two types of photoresists, positive and negative photoresists, used for different applications. In positive resists, the exposed area is soluble, and in negative resists, the exposed area is insoluble for wet chemical development.

Features of positive resists.

Excellent resolution, stable to developers, can be developed in aqueous developers. Bad resist in etching or injection process, poor wafer adhesion

Negative adhesive features.

High sensitivity but average adhesion, excellent resistance to etching or injection processes, cheaper than positive resist, lower resolution Requires organic developer (toxic)

For patterning of wafers in manufacturing, almost exclusively positive resists are used Negative resists are used primarily as passivation layers and can be cured by UV radiation.

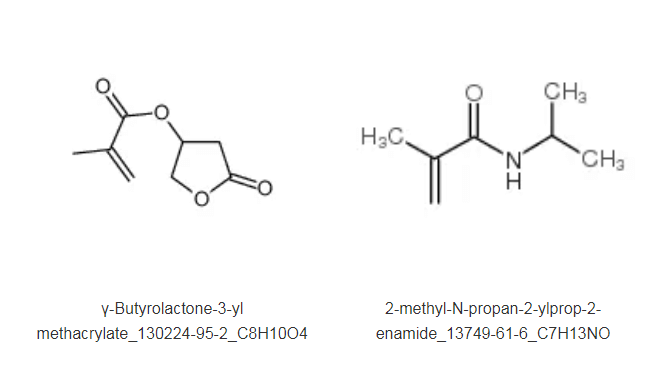

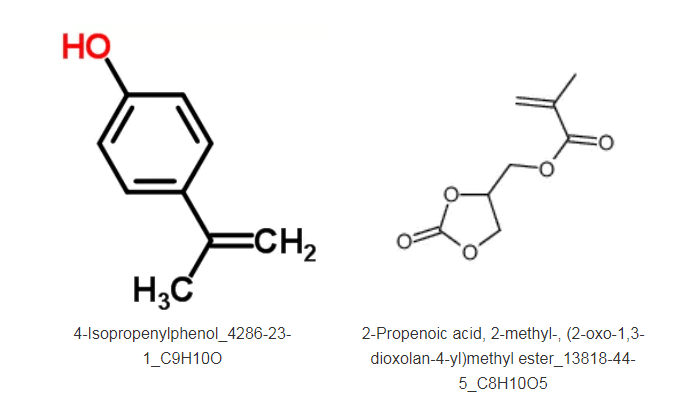

Chemical composition

Photoresists consist of a binder, a sensitizer and a solvent.

Binder (~20%)

A phenolic varnish is used as the binder, which is a synthetic resin used to control the thermal properties of the resist.

Sensitizer (~10%)

The sensitizer defines the photosensitivity of the resist. The sensitizer consists of molecules that can affect the solubility of the resist if it is exposed to high energy radiation. Therefore lithography must be performed in an area with low-energy ambient light.

Solvent (~70%)

The solvent defines the viscosity of the resist. By annealing, the solvent evaporates and the resist is stabilized.

Please follow UIV chem to find more chemical materials.