OLED, or organic light-emitting diode, is also known as organic electromechanical laser display. Since 2003, this display device has been widely used in MP3 players because of its thin, light and power-saving characteristics. oled screens have many advantages that LCDs cannot match, and in recent years, oled has become the focus of industry attention, especially the iPhone x smartphone using oled screens will further promote the industrial application of oled technology.

UIVChem will give a brief description of the materials used in OLEDs, which mainly include anode, cathode, transmission layer and light-emitting layer materials, as well as film materials and packaging materials.

Anode Materials

The anode material of OLED is mainly used as the anode of the device, which requires the highest possible work function in order to improve the hole injection efficiency, while the OLED device requires that one side of the electrode must be transparent, so the general use of Au, transparent conductive polymers (such as polyaniline) and ITO conductive glass, commonly used ITO glass.

Cathode materials

OLED cathode material is mainly used as the cathode of the device, the lower the metal work function of the cathode material, the easier the electron injection, the higher the luminous efficiency, the less Joule heat generated in the work, the device life will have a greater increase.

The cathode of OLED usually uses single-layer metal cathode, alloy cathode, layer cathode, doped composite electrode, etc.

Transport layer materials

OLED devices require the injection of holes and electrons into the light-emitting layer should be basically the same rate, so it is necessary to choose the appropriate hole and electron transport materials. Tests are usually selected NPB as the hole transport layer, and the choice of Alq3 as the electron transport material.

Luminous layer material

Luminous material is the most important material in OLED devices, generally light-emitting materials should have high luminous efficiency and good electron or hole transport properties. Luminous materials between organic and inorganic, both organic high fluorescence quantum efficiency, but also inorganic high stability.

Film Materials

Optical films are the key materials in LCD and AMOLED panels. Traditional polarizers are mainly made of a combination of various compensation films such as TAC and PVA. COP films with better mechanical, temperature and weather resistance are used.

Encapsulation Materials

Thin film encapsulation is the mainstream technology of encapsulation nowadays. Inorganic-organic composite encapsulation materials combine the advantages of good water and oxygen barrier of inorganic encapsulation materials and good film formation of organic encapsulation materials, and are the mainstream choice of OLED encapsulation materials.

The production process of OLED materials, first from the chemical raw materials synthesis of OLED intermediates, intermediates synthesis of pre-sublimation materials (monomer), and then sublimation and purification, the formation of OLED terminal materials. oled terminal materials production and organic materials technology in the hands of foreign companies, while domestic enterprises are mainly engaged in OLED intermediates and monomer production of crude products.

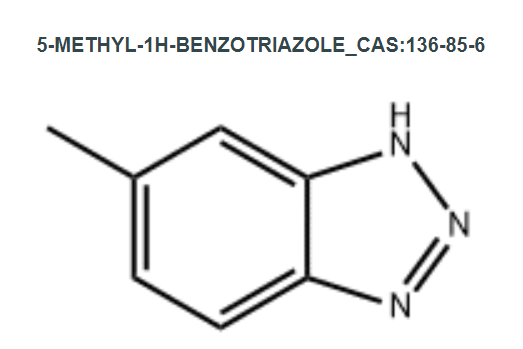

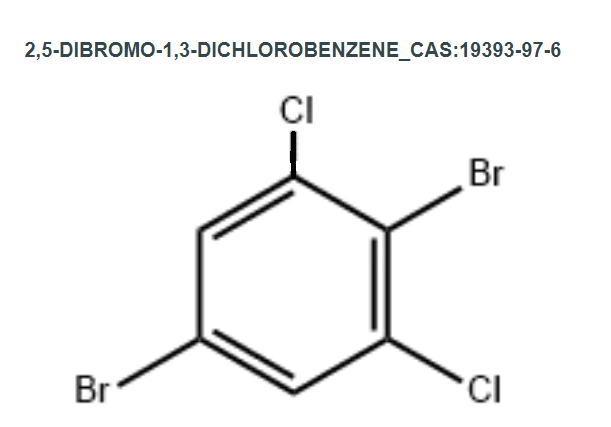

There are many common intermediate materials. UIVChem sells 5-METHYL-1H-BENZOTRIAZOLE, 2,5-DIBROMO-1,3-DICHLOROBENZENE, etc. You can find them according to CAS number.

OLED materials will predictably boom in the future, and Chinese domestic intermediate manufacturers are accelerating the pace. If you want to know more, please contact our experts.