| Identification | ||

| Name |

|

Grela 2nd Generation |

| Synonyms |

|

nitro-Grela |

|

|

||

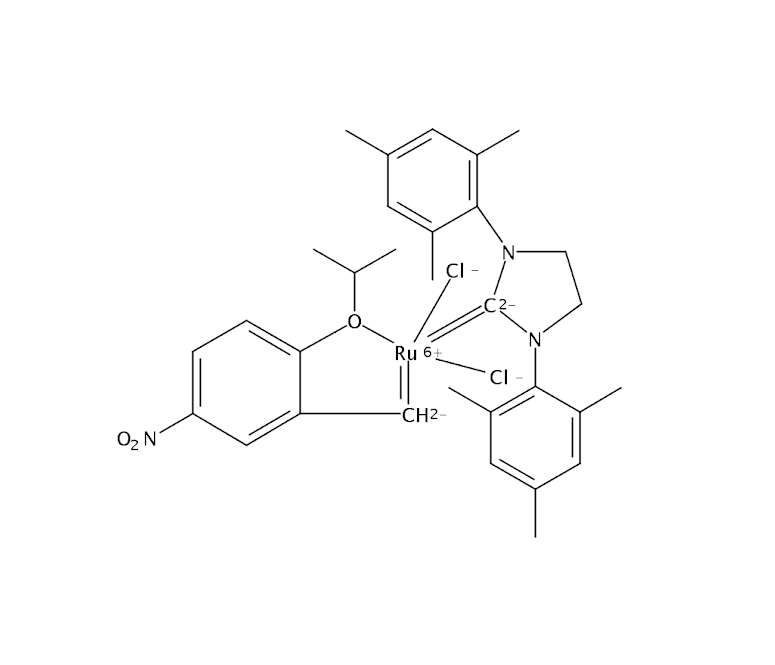

| Molecular Structure |

|

|

|

|

||

| Molecular Formula |

|

C31H36Cl2N3O3Ru |

| Molecular Weight |

|

670.62 |

| CAS Registry Number |

|

502964-52-5 |

|

EINECS |

|

|

| Properties | ||

| Color |

|

green |

|

Boiling point |

|

>300 ºC |

| Form |

|

Powder |

| Storage Condition |

|

2-8 ºC |

|

|

||

|

|

||

|

|

||

I. Applications of GRELA 2nd Generation Catalyst

1.Polyolefin Production

Mainly used in industrial-scale production of high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and isotactic polypropylene (iPP).

Enables precise control over polymer molecular weight distribution, branching, and stereoselectivity, making it suitable for high-end plastics (e.g., transparent packaging materials, high-impact automotive components).

2.Comonomer Incorporation

Exhibits higher activity for α-olefin copolymerization (e.g., 1-butene, 1-hexene), producing copolymers with superior mechanical properties.

3.Energy-Efficient Processes

Can operate at lower temperatures/pressures in some cases, reducing energy consumption.

II. Comparative Analysis with Alternatives

1. Comparison with Ziegler-Natta (Z-N) Catalysts

|

Parameter |

GRELA 2nd Gen Catalyst |

Traditional Z-N Catalyst |

|

Activity |

Higher (improved yield per metal center) |

Lower, requires excess cocatalyst (e.g., AlEt₃) |

|

Stereoselectivity |

Excellent (isotacticity >99%) |

Requires external donors, less selective |

|

Copolymerization |

Efficient long-chain α-olefin incorporation |

Uneven comonomer distribution, blocky structures |

|

Product Purity |

Low metal residue, no need for deashing |

Requires post-treatment to remove residues |

|

Cost |

Higher (proprietary technology) |

Low-cost, mature industrial process |

2. Comparison with Metallocene Catalysts

|

Parameter |

GRELA 2nd Gen Catalyst |

Metallocene Catalysts |

|

Structural Flexibility |

Tunable ligands but somewhat limited |

Highly customizable (e.g., Cp ligands) |

|

Polar Monomer Tolerance |

Some systems tolerate polar monomers |

Generally sensitive to polar impurities |

|

Process Compatibility |

Adapts to existing Z-N equipment |

Requires strict oxygen/moisture-free conditions |

|

Cost |

Lower than metallocenes |

Expensive (requires MAO cocatalyst) |

III. Key Advantages

High Activity & Selectivity: Single-site characteristics minimize side reactions, ensuring product uniformity.

Eco-Friendliness: Low metal residues, compliant with food/medical-grade material standards.

Process Adaptability: Balances metallocene performance with Z-N cost efficiency.