2-Ethyl-2-adamantyl methacrylate_CAS:209982-56-9_EAMA

2-Ethyl-2-adamantyl methacrylate (C16H24O2) is the ideal choice for enhancing the strength and stability of your products. Order now to elevate your materials with this advanced compound.

2-Ethyl-2-adamantyl methacrylate_CAS:209982-56-9

| Identification | ||

| Name |

|

2-Ethyl-2-adamantyl methacrylate |

|

Synonyms |

|

2-ethacryloyloxy-2-methyladamantane 2-Ethyladamant-2-yl methacrylate (2-ethyl-2-adamantyl) 2-methylprop-2-enoate Methacrylic Acid 2-Ethyl-2-adamantyl Ester 2-ethyladamantan-2-yl 2-methylprop-2-enoate EADM |

|

|

||

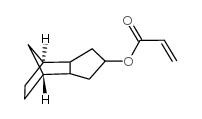

| Molecular Structure |

|

|

|

|

||

| Molecular Formula |

|

C16H24O2 |

| Molecular Weight |

|

248.36 |

|

CAS Registry Number |

|

209982-56-9 |

| Properties | ||

| Melting point |

|

40 °C |

|

Boiling point |

|

318.3±11.0 °C |

|

Density |

|

1.04±0.1 g/cm3 |

|

Storage conditions |

|

<0°C |

Engineering Plastics: Utilized in the production of high-performance plastics that require both thermal stability and mechanical strength. These materials are often used in aerospace, automotive, and industrial applications.

Coatings and Adhesives: Added to coatings and adhesives to improve their abrasion resistance, chemical resistance, and adhesion properties, extending the lifespan and effectiveness of these products.

Synthetic Rubbers: Employed as a monomer in the synthesis of advanced rubber materials, providing enhanced elasticity, resilience, and longevity.

Specialty Resins: Incorporated into specialty resins for various applications including electronics, medical devices, and high-performance composites, where its properties contribute to the overall performance and reliability of the materials.

Storage: Store in a cool, dry place, away from direct sunlight and incompatible materials. Containers should be tightly sealed to prevent moisture absorption and contamination.

Safety Precautions: Handle with care in a well-ventilated area. Use appropriate personal protective equipment (PPE) such as gloves, safety goggles, and lab coats. Avoid inhalation and contact with skin and eyes.

Coatings and Adhesives: Added to coatings and adhesives to improve their abrasion resistance, chemical resistance, and adhesion properties, extending the lifespan and effectiveness of these products.

Synthetic Rubbers: Employed as a monomer in the synthesis of advanced rubber materials, providing enhanced elasticity, resilience, and longevity.

Specialty Resins: Incorporated into specialty resins for various applications including electronics, medical devices, and high-performance composites, where its properties contribute to the overall performance and reliability of the materials.

Storage: Store in a cool, dry place, away from direct sunlight and incompatible materials. Containers should be tightly sealed to prevent moisture absorption and contamination.

Safety Precautions: Handle with care in a well-ventilated area. Use appropriate personal protective equipment (PPE) such as gloves, safety goggles, and lab coats. Avoid inhalation and contact with skin and eyes.