1-Isopropylcyclopentylmethacrylate_CAS:1149760-04-2

2-Propenoic acid, a key component in photoresist materials. Interested in how 2-Propenoic acid can enhance your products? Leave a comment or message us today to learn more!

1-Isopropylcyclopentylmethacrylate_CAS:1149760-04-2

| Identification | ||

| Name |

|

1-Isopropylcyclopentylmethacrylate |

| Synonyms |

|

IPCPMA

2-Propenoic acid, 2-methyl-, 1-(1-methylethyl)cyclopentyl ester |

|

|

||

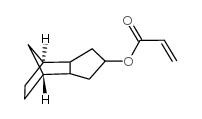

| Molecular Structure |

|

|

|

|

||

| Molecular Formula |

|

C12H20O2 |

| Molecular Weight |

|

196.29 |

| CAS Registry Number |

|

1149760-04-2 |

| Properties | ||

| Density |

|

0.94±0.1 g/cm3 |

|

Boiling point |

|

239.9±9.0 °C |

1-Isopropylcyclopentylmethacrylate uses:

1-Isopropylcyclopentylmethacrylate is used as a photoresist material.

1-Isopropylcyclopentylmethacrylate is a specialized monomer that has gained significant attention in the semiconductor industry, particularly as a key component in photoresist materials. Photoresists are crucial in the lithography process, where they enable the precise patterning of semiconductor wafers, a fundamental step in the manufacturing of integrated circuits and other microelectronic devices.

Photoresists are light-sensitive materials that undergo chemical changes when exposed to specific wavelengths of light, typically in the ultraviolet (UV) spectrum. The unique properties of 1-Isopropylcyclopentylmethacrylate make it particularly suitable for use in advanced photoresist formulations:

High Sensitivity: The chemical structure of 1-Isopropylcyclopentylmethacrylate allows for rapid and efficient photo-induced polymerization, which is crucial for achieving fine resolution in lithographic processes.

Thermal Stability The compound’s robust thermal properties ensure that it remains stable during the various stages of semiconductor processing, including baking and etching, which often involve high temperatures.

Excellent Film-Forming Ability: It provides a uniform, defect-free coating on semiconductor wafers, essential for precise pattern transfer and minimizing defects in microelectronic devices.

Good Adhesion: Ensures strong adherence to substrates, preventing delamination during processing and improving the overall yield and reliability of the semiconductor devices.

High Sensitivity: The chemical structure of 1-Isopropylcyclopentylmethacrylate allows for rapid and efficient photo-induced polymerization, which is crucial for achieving fine resolution in lithographic processes.

Thermal Stability The compound’s robust thermal properties ensure that it remains stable during the various stages of semiconductor processing, including baking and etching, which often involve high temperatures.

Excellent Film-Forming Ability: It provides a uniform, defect-free coating on semiconductor wafers, essential for precise pattern transfer and minimizing defects in microelectronic devices.

Good Adhesion: Ensures strong adherence to substrates, preventing delamination during processing and improving the overall yield and reliability of the semiconductor devices.